UNIFILL

|

|||||||||

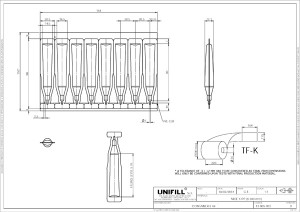

| UNIFILL is the leading monodose technology innovator - The ULTRACLEAN MONODOSE TECHNOLOGY is now the Breaking & the Most Economic Solution for Manufacturing Sterile Eye Drops in addition to Autoclavable single dose dosage forms-Both the initial & running cost of our ULTRACLEAN MONODOSE TECHNOLOGY are very much less as compared to the BFS Technology    UNIFILL monodose technology is particularly suitable for the packing of OTC liquid and semi-dense products such as medical syrups, energetic drinks, mouth washers, ointments, pain-relief creams, tooth-pastes, etc. UNIFILL monodose technology is particularly suitable for the packing of OTC liquid and semi-dense products such as medical syrups, energetic drinks, mouth washers, ointments, pain-relief creams, tooth-pastes, etc.

HYGENE LEVEL The U-C package includes the thermoforming with sterile forming, magnetic dosing systems, laminar flow units with HEPA filter, inert gas flushing, 316L recovery trays, special guardings, etc. SUPPOSITORIES Easy and quick size changeover operations, balcony-type construction for immediate tooling access, lowest material waste, in-production reel replacement and many other features. Several versions for outputs starting from 10,000 and reaching up to 35,000 suppositories per hour.

|

|||||||||

|

UNIFILL is widely recognized as the world leader in the manufacturing of Vertical Thermoform Fill & Seal machines for plastic unit doses serving the Food, the Pharmaceutical, the Personal Care and the Chemical industry. Over the last three decades, many worldwide customers have launched a variety of unit dose concept products made on UNIFILL machines. Among them are also some of the world’s renowned multinationals such as Nestlé, Unilever, MD Foods, Bongrain, Danone, Kraft, Bayer, Colgate Palmolive, Procter & Gamble, Sanofi-Aventis, Reckitt Benckiser, Sara Lee, Johnson Wax, Garnier, L’Oréal and many others. UNIFILL has the know-how and the experience it takes to make a monodose project successful and to guide the customer through all the project stages.This is what we have called the “Monodose Experience Package”

|

|||||||||

Leave a Reply